10 benefits of Additive Manufacturing

Additive Manufacturing (AM) is not new. Over the recent decades, as the technology behind AM (also known as 3D printing) improved and prices fell, many

Cross have pioneered the design, development and manufacture of brush seals since 1976, and continue to push the boundaries of brush seal applications by designing for additive manufacturing.

Cross have pioneered the design, development and manufacture of brush seals since 1976, and continue to push the boundaries of brush seal applications by designing for additive manufacturing.

As additive manufacturing technology continues to grow in both popularity and practical uses, here at Cross we want to continue pushing the boundaries of brush seal applications by designing our brush seal technology for enhanced processing in additive manufacturing.

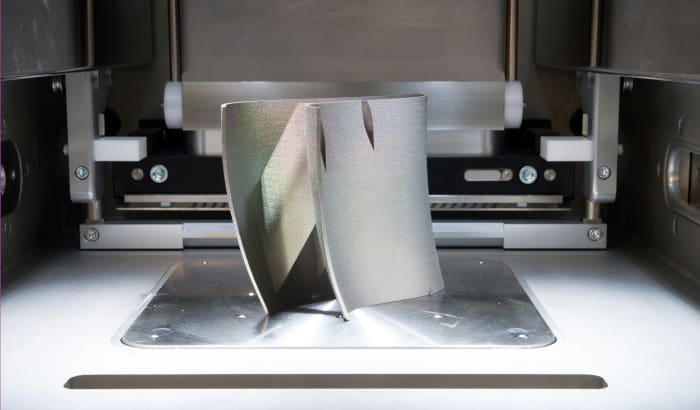

Brush seals are traditionally used in gas and steam turbines in the Aerospace and Power Generation industries, but they can also be used in additive manufacturing for effective powder distribution in place of typical powder scrapers such as rollers, blades and lips.

As brush seals contain thousands of fine wires, they can provide excellent powder distribution and chamber sealing for additive manufacturing and offer a range of other benefits:

Get in touch with us and one of our team can talk to you about how we can help you with your additive manufacturing requirements

Additive Manufacturing (AM) is not new. Over the recent decades, as the technology behind AM (also known as 3D printing) improved and prices fell, many

The manufacturing of tools and components is certainly not a new activity! Ever since human life evolved, mankind has been making things, from spear heads

Our dedicated customer service teams are waiting to hear from you. To reach the right team please give us brief details and press submit.

You can also call our main office line on +44 (0)3301 224 400.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |