Home » Products & Applications » Retaining Rings & Circlips

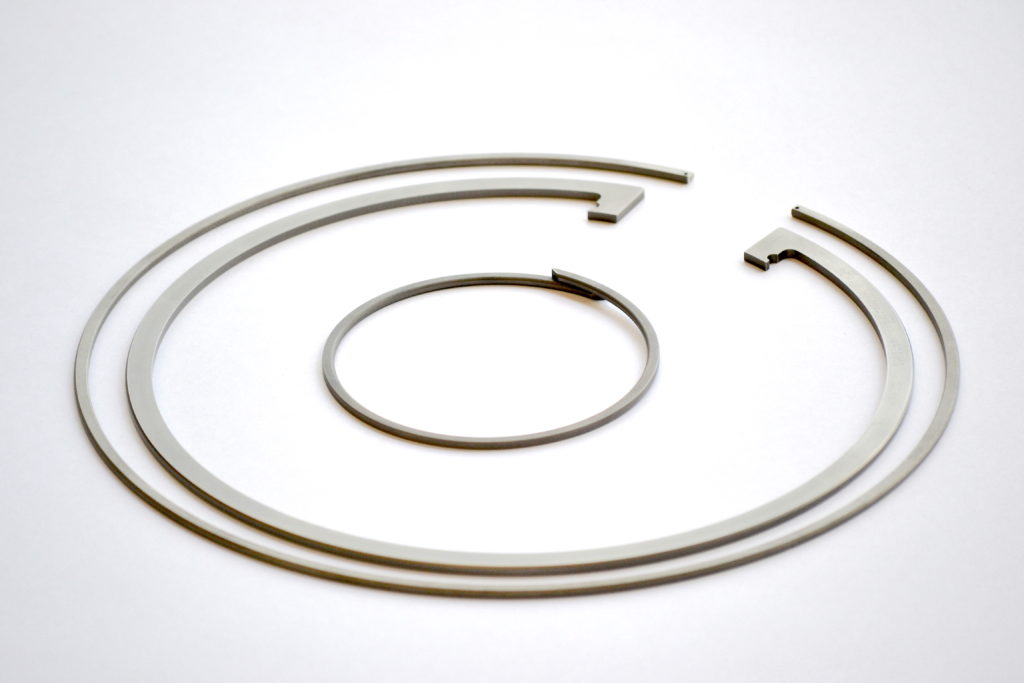

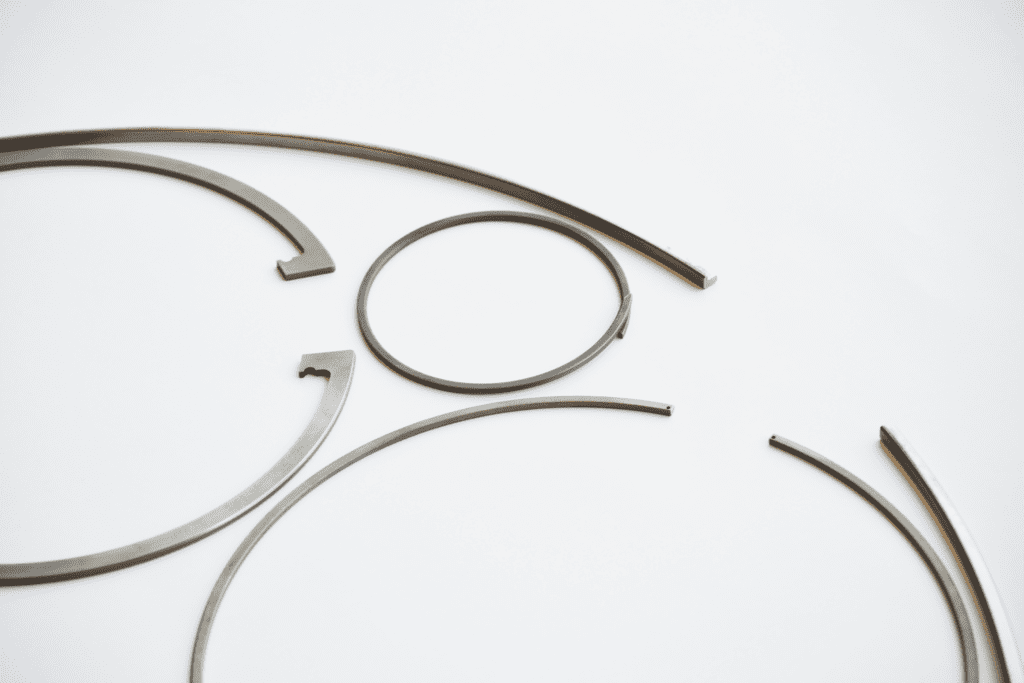

Cross Retaining Rings and Circlips for use in extreme temperatures and challenging environments benefit from decades of development, design and manufacturing expertise. The Cross proprietary forging process produces high strength and high integrity Retaining Rings and Circlips from alloy wire or rod.

We offer a complete package for design and manufacture, including the detailed design of customised grooves and housings. Our experience gained over many years is available as a free consultancy service. The choice of materials is complex; advice offered is based on test results from our in-house metallurgical laboratory and experience of making rings in different alloys, such as Waspaloy, Titanium, Inconel 718 and X750 for diverse conditions.

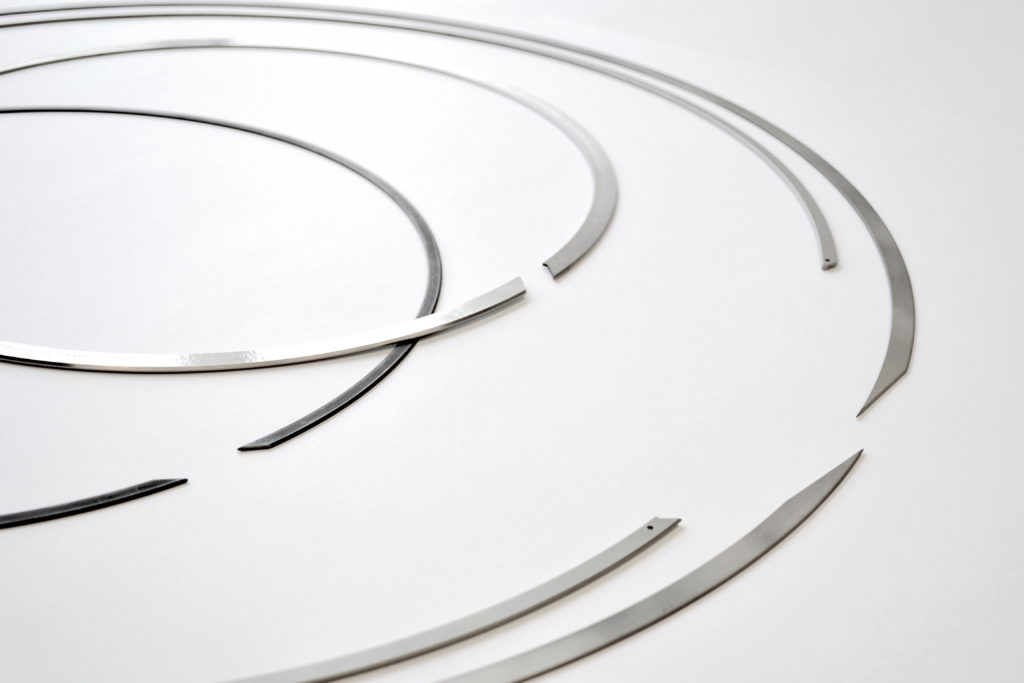

The Cross ranges of Circlips and Retaining Rings are available in any Ø size range 0.2″ (5mm) to 79″ (2000mm).

Many standard catalogue sizes are held in stock for rapid delivery.

Specially designed Cross Retaining Rings are a well proven method of retaining compressor and turbine blades to the rotating drum in modern aircraft engines, combining a speedy assembly technique with reliable blade retention. Holding the blades in place at high speeds and temperatures demands a rugged and lightweight ring design.

Our proprietary method transforms wire or rod into the required section for engine geometry. This process offers significant improvements in mechanical properties over rings machined from sheet or forgings, including a very precise circumferential fit and enough spring to hold them in position at operating temperatures up to 800°C.

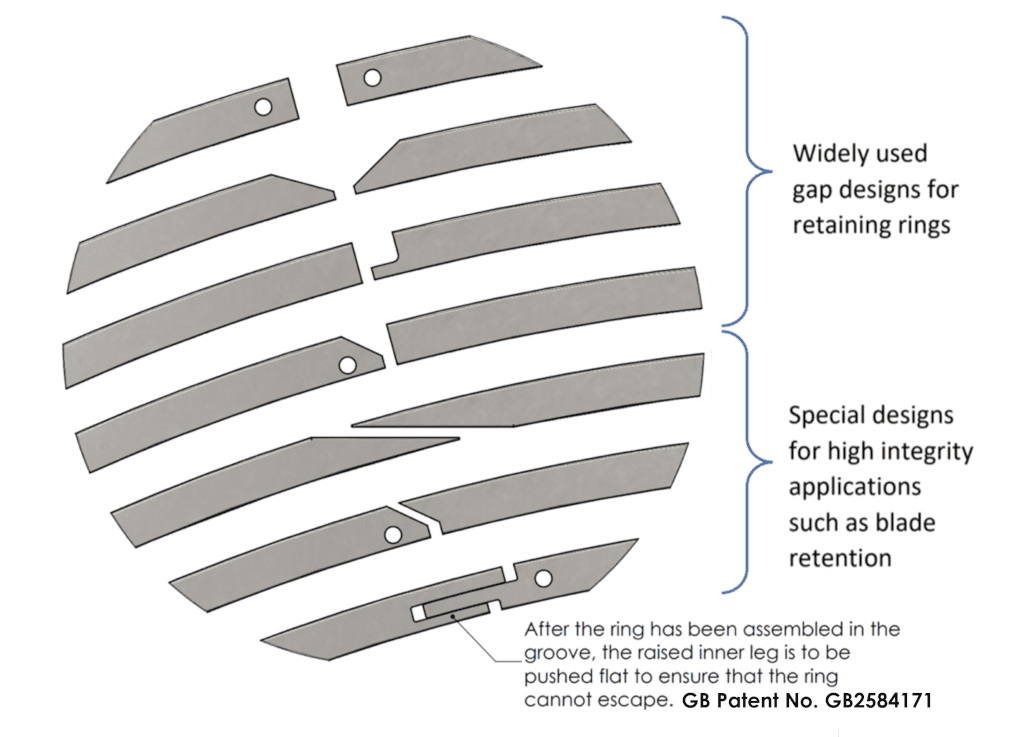

Rings can be dynamically balanced for optimum rotational performance and produced with a range of gap configurations, many of which have been designed by Cross to meet different engine manufacturers’ specifications.

The environmentally efficient Cross forging process produces Retaining Rings and Circlips of the highest quality, strength and accuracy, whilst minimising waste and optimising the use of materials.

Cross Retaining Rings can be manufactured with a range of different gap designs, from widely used types to more specialist applications and high operating temperatures

Stiffness, available space and geometry are all deciding factors in the design, as are axial loads and operating temperatures, up to 800°C.

Our dedicated customer service teams are waiting to hear from you. To reach the right team please give us brief details and press submit.

You can also call our main office line on +44 (0)3301 224 400.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |