Home » Products & Applications » Sealing Rings

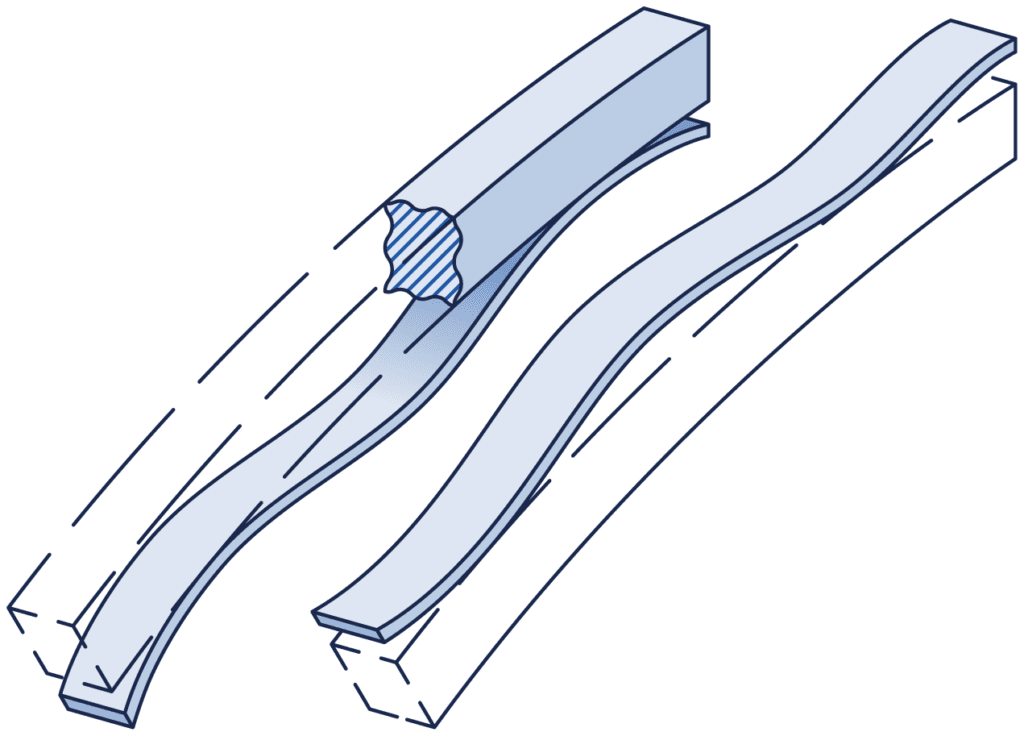

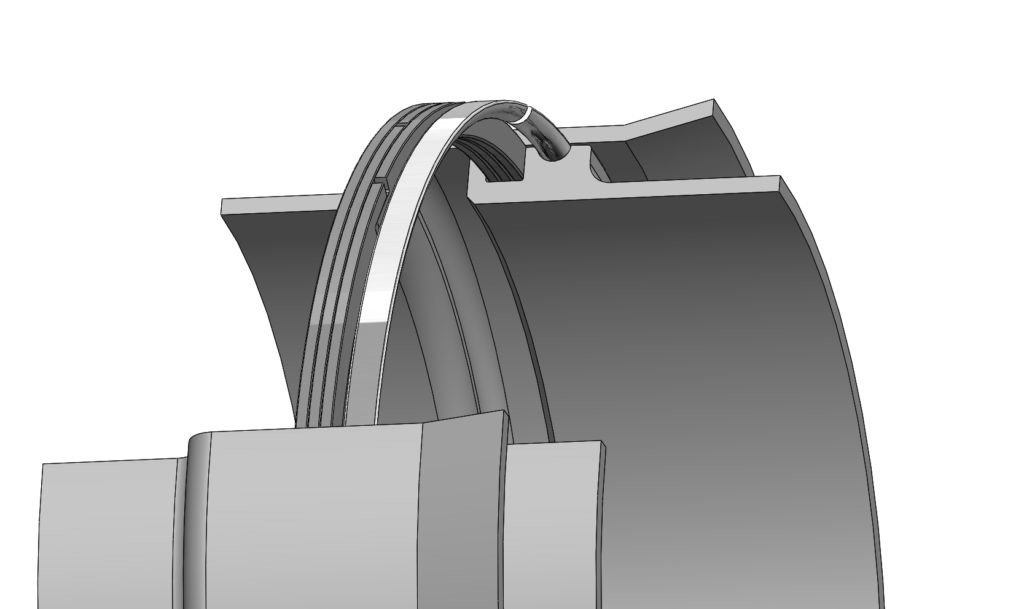

Cross Manufacturing Sealing Rings are manufactured using a proprietary forging process that creates high strength and high integrity products from alloy wire or rod.

We apply over eighty years of dedicated experience to the development, design and manufacture of metallic Sealing Rings for long term reliability in high temperature and challenging environments.

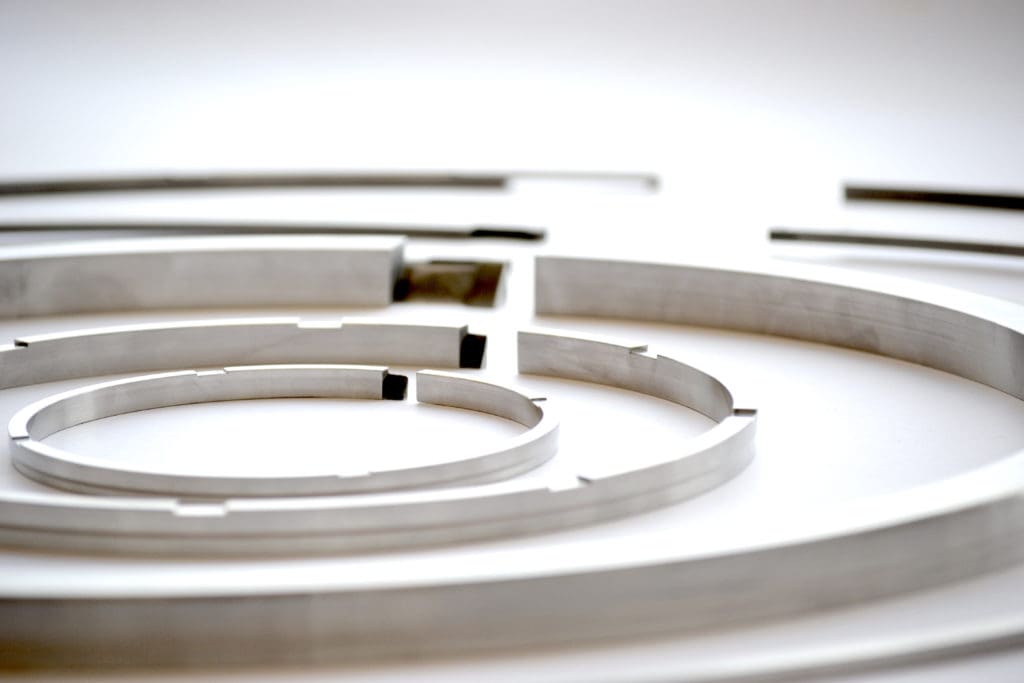

Our manufacturing capabilities encompass an unrivalled combination of materials, designs and sizes.

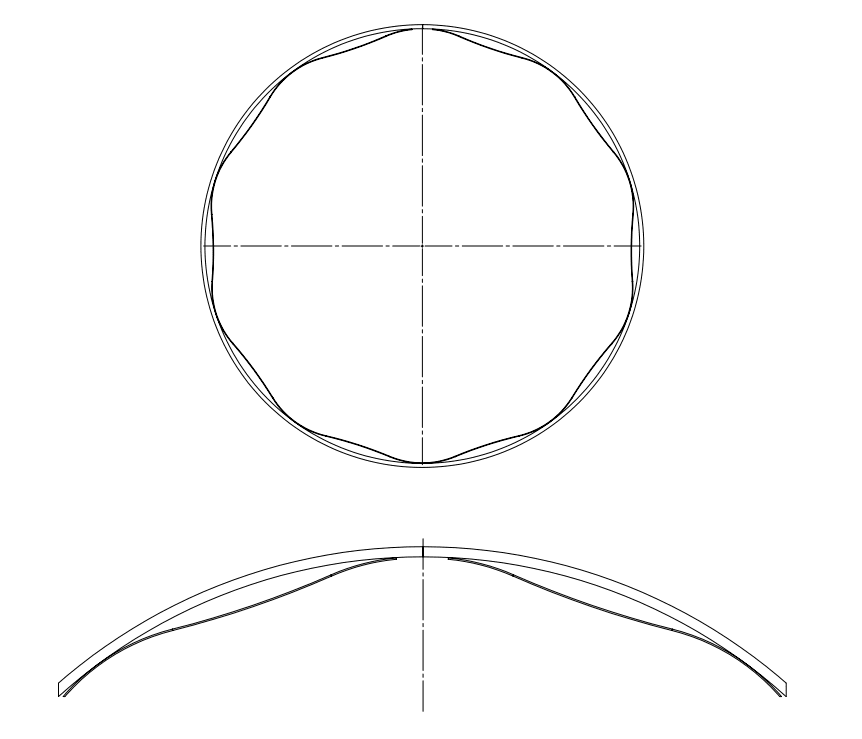

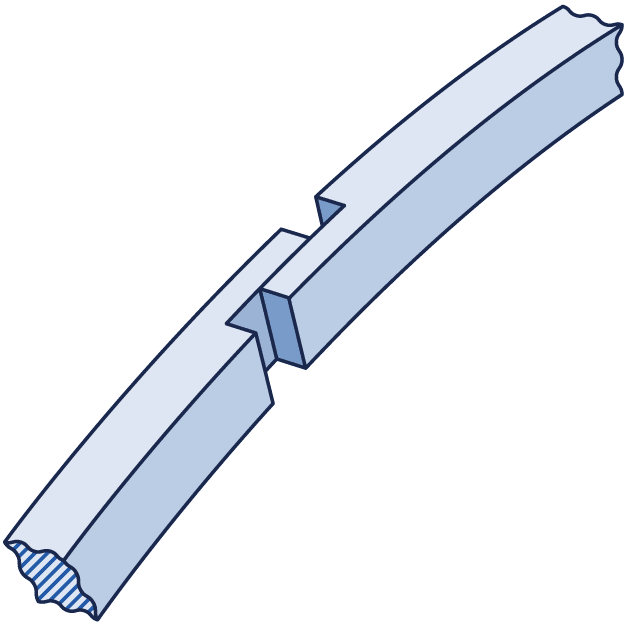

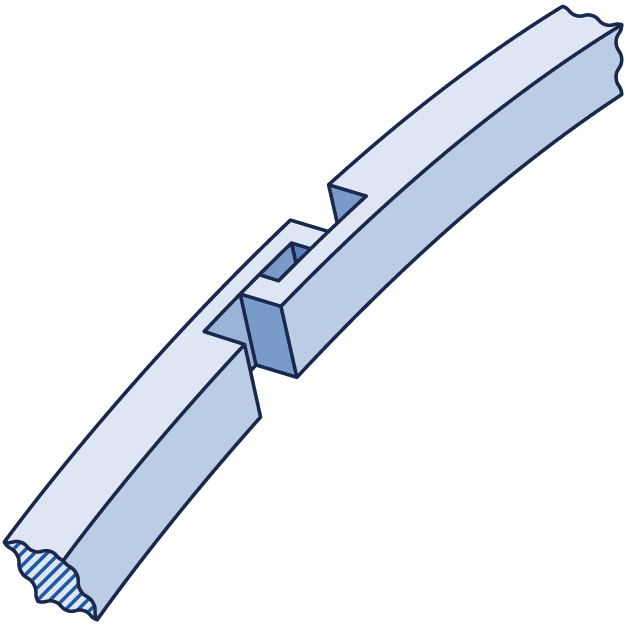

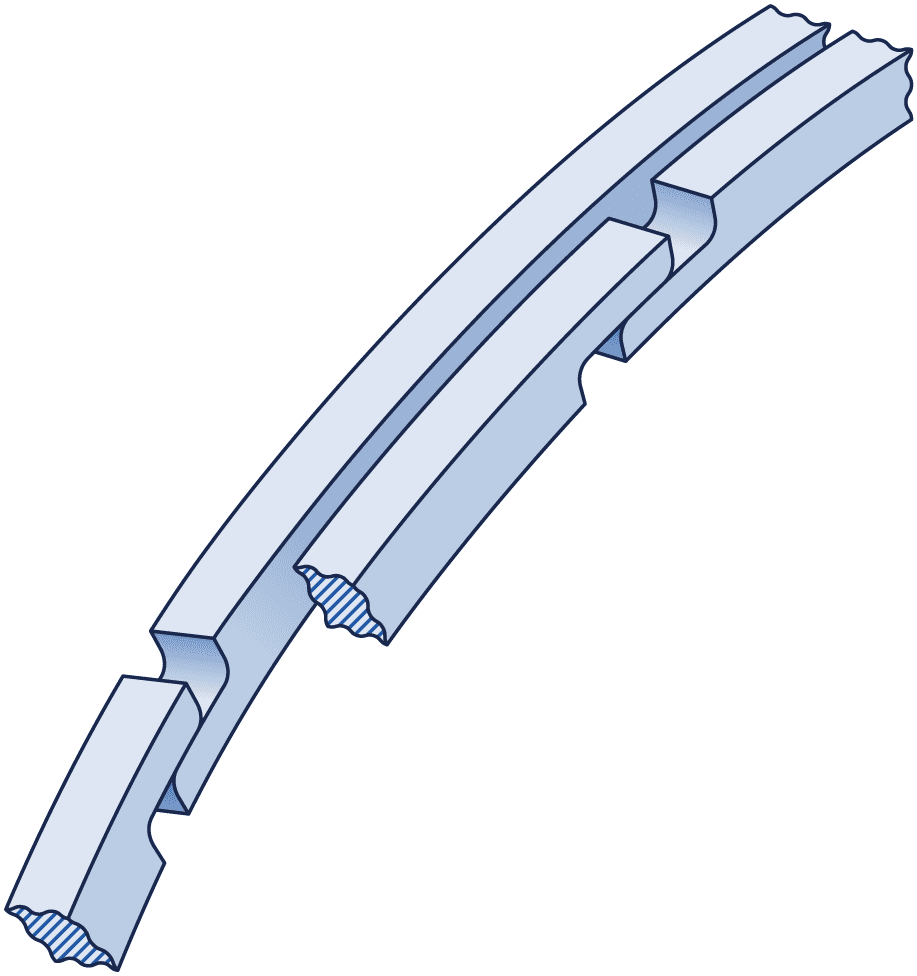

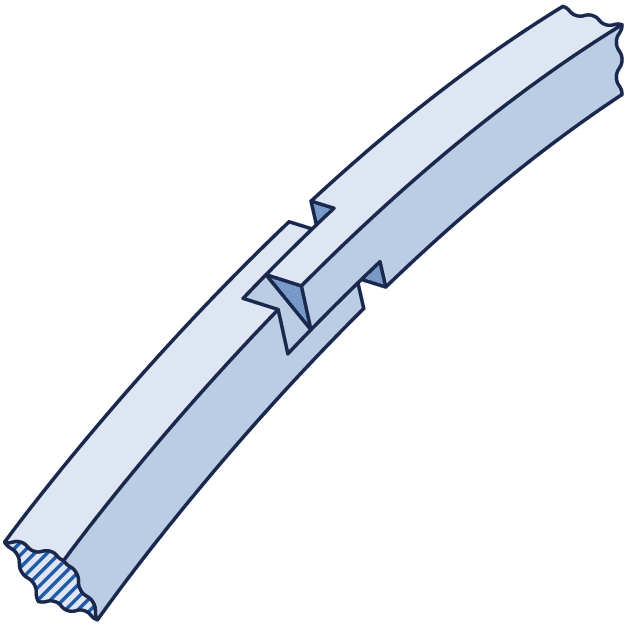

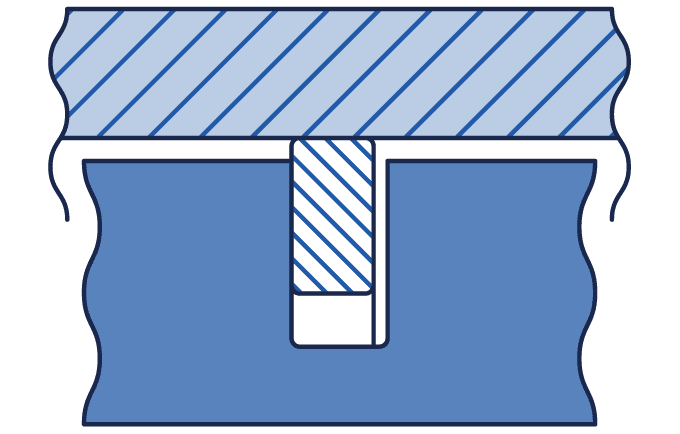

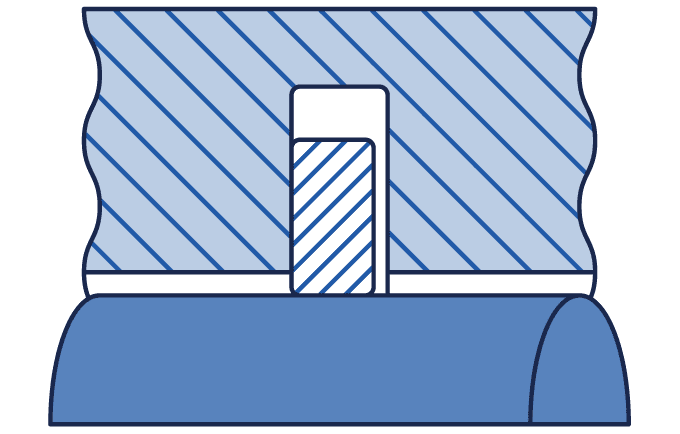

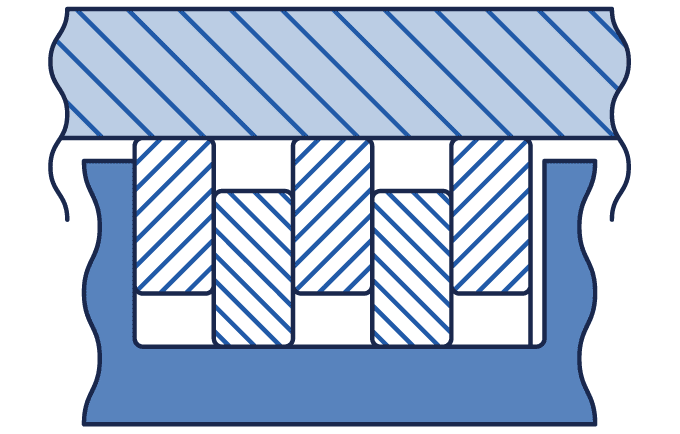

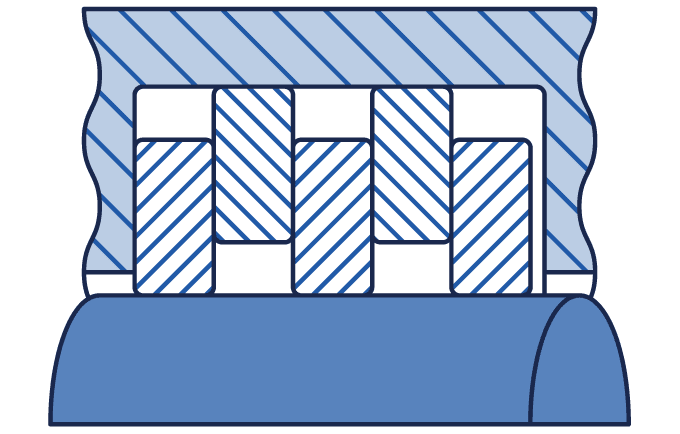

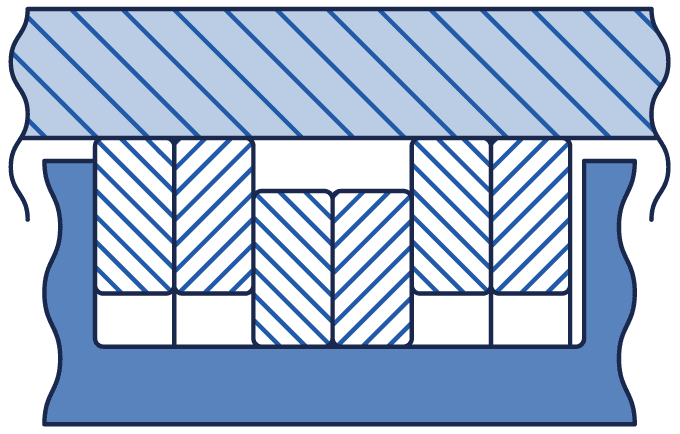

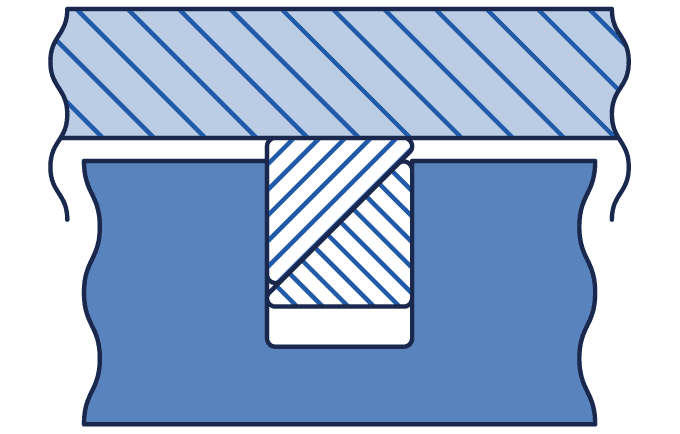

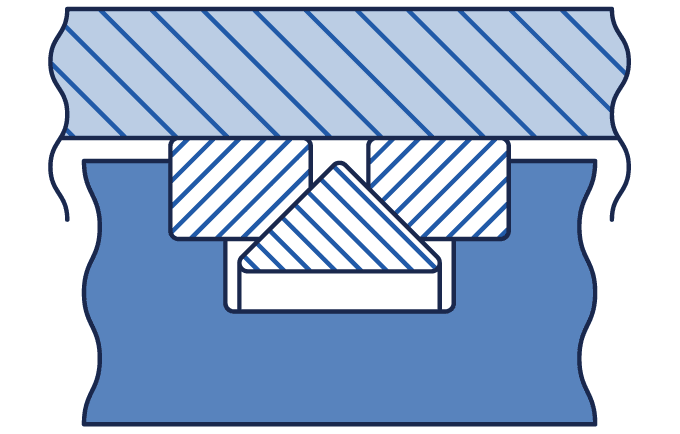

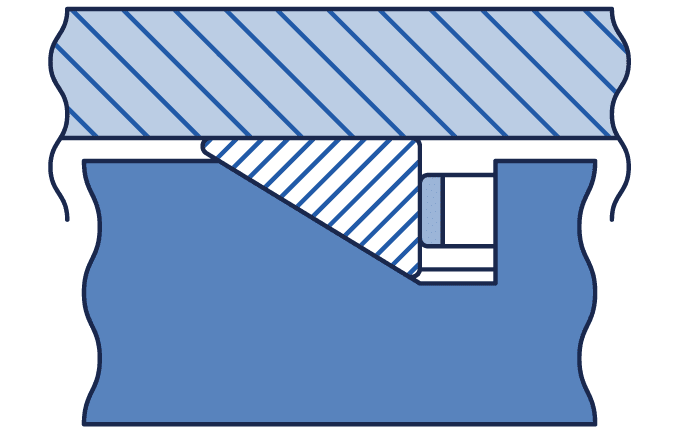

To meet virtually any specific application, our designs include in-springing and out-springing Sealing Rings and Ring Packs, with or without cockle springs.

Virtually any customised sectional requirements are possible.

Sealing Rings with Ø up to 79″ (2000mm) are in regular production.

Our proven expertise with material choices facilitates Sealing Ring applications in temperatures of 1000°C.

We hold large stocks of aerospace standard heat resisting alloys, mostly in wire and bar form.

The list includes:

Nimonic® 75; Nimonic® 80A; Nimonic® 90; Nimonic® C.263; Inconel® 600; Inconel® 625; Inconel® 718; Inconel® X.750; Haynes® 25 (L.605); Haynes® 282; Incoloy® A.286; Waspaloy.

We are an approved Sealing Ring supplier to companies in worldwide industries including aerospace, power generation, oil, gas and chemical production. Applications include aircraft and marine engines, gas and steam turbines, power plants, pipeline booster stations and process control.

A complete package for design and manufacture of Sealing Rings is available, including the detailed design of customised grooves and housings.

The experience we have gained over many years is available as a consultancy service to our clients.

The choice of materials is complex and we offer advice based on test results from our in-house metallurgical laboratory and experience of making rings in different alloys for a diverse range of conditions.

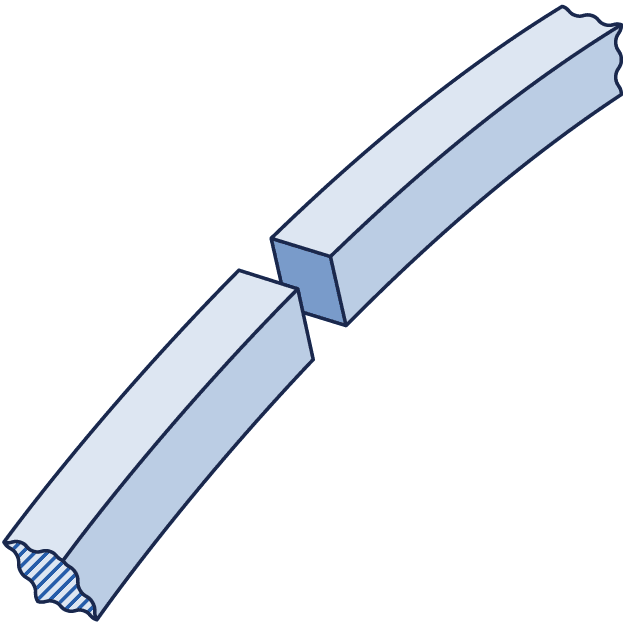

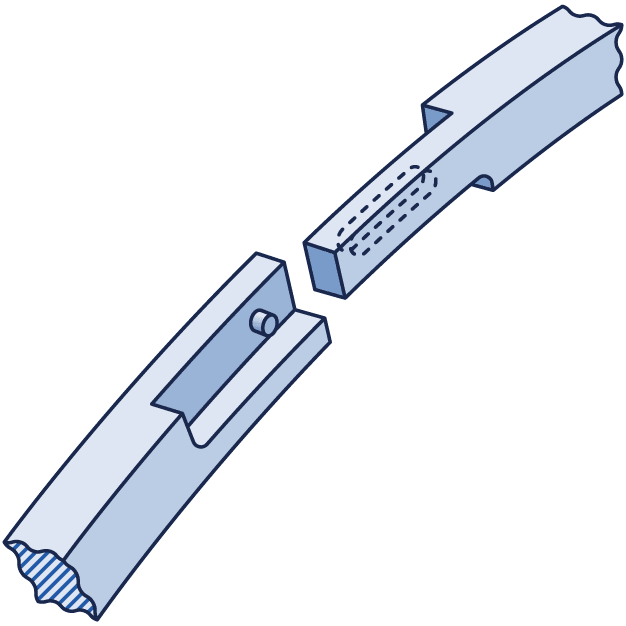

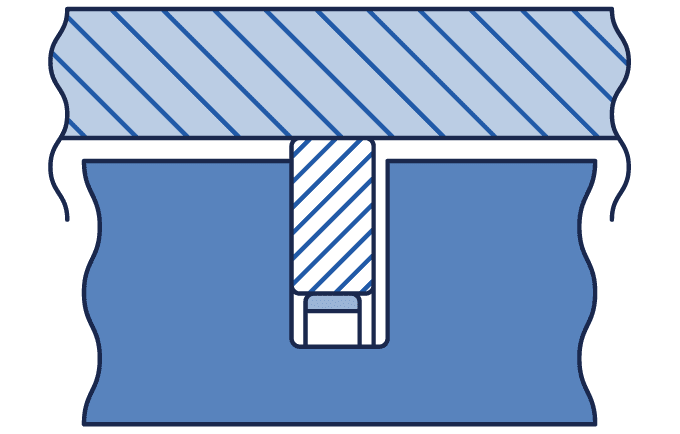

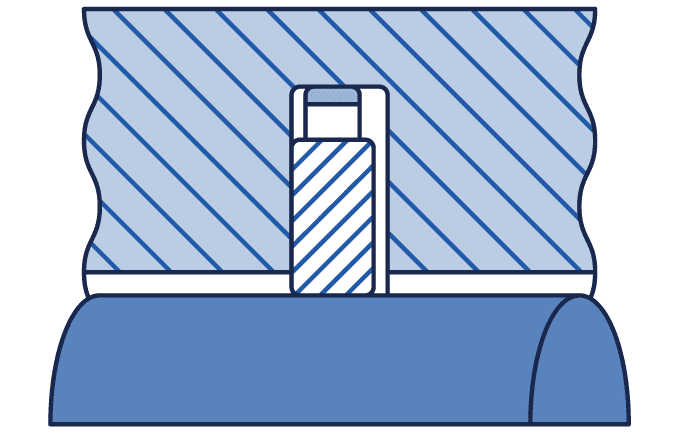

Cross Pipe Joint Sealing Rings are designed for sealing gases at high temperatures and pressures. The easy push-fit assembly accommodates up to 3.5° misalignment and the design allows for unrestricted rotational and axial movement.

Our dedicated customer service teams are waiting to hear from you. To reach the right team please give us brief details and press submit.

You can also call our main office line on +44 (0)3301 224 400.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |