Home » Products & Applications » Brush Seals

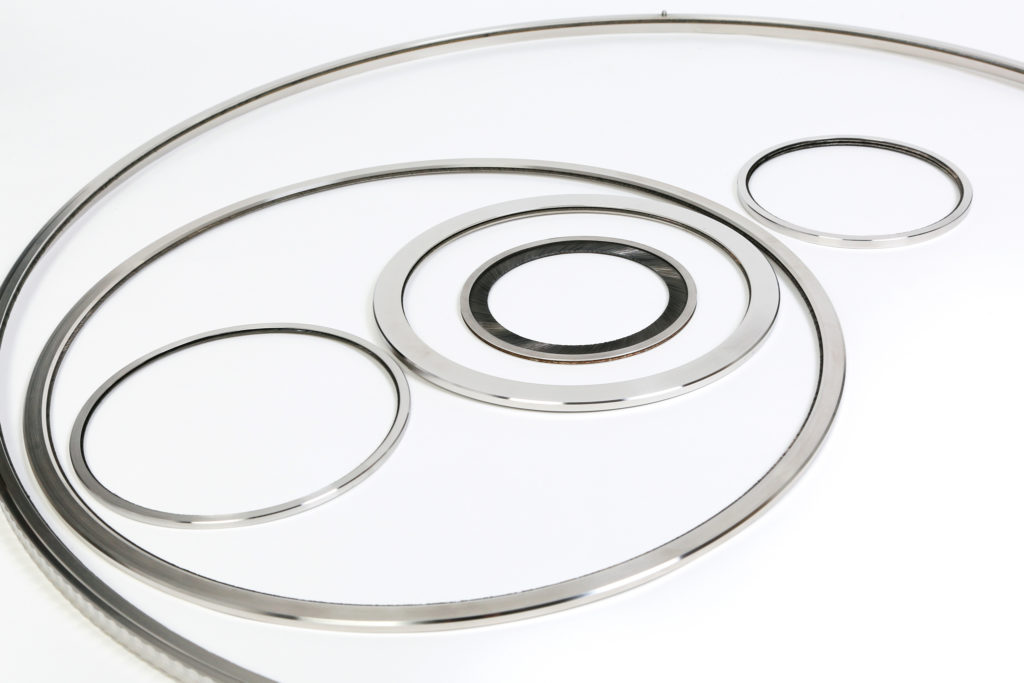

Cross have pioneered the design, development and manufacture of aerospace and power generation brush seals since 1976, utilising inhouse test facilities, design tools and bespoke machinery.

Cross have developed the capability of providing sealing solutions tailored to deliver superior performance under the demanding conditions encountered in turbomachinery.

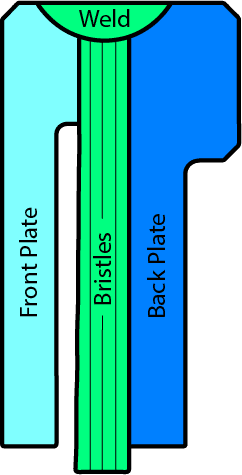

A brush seal contains many thousands of fine wires, which touch the rotor, forming an effective barrier to gas flow, whilst retaining the ability to deflect during shaft excursions and thermal movements without permanent loss of sealing efficiency.

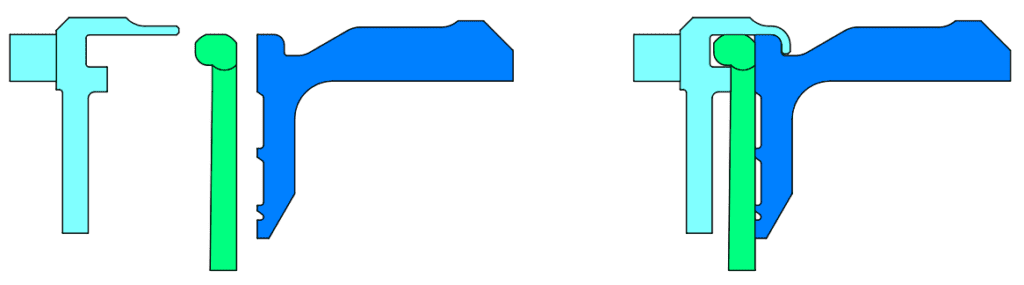

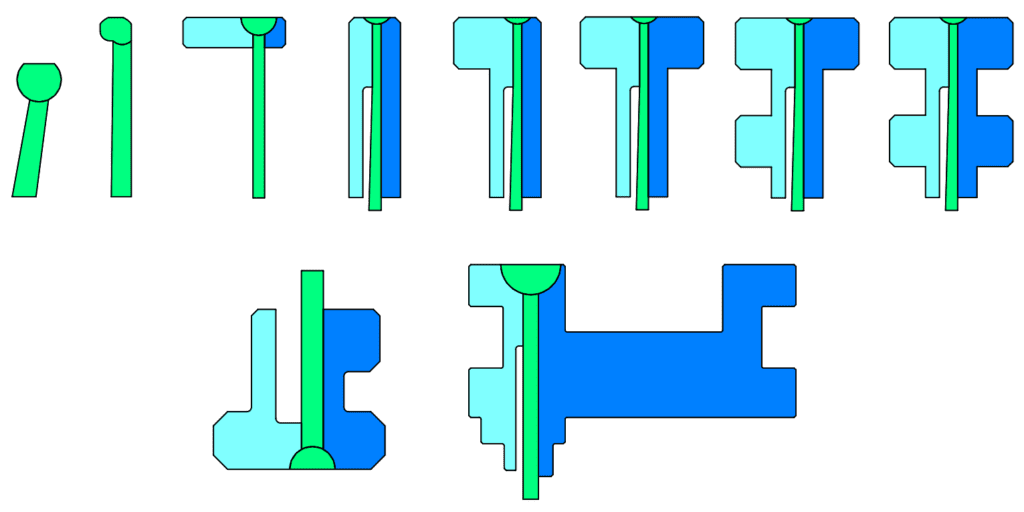

A small selection of our typical Brush Seal section where we can incorporate anti-rotation slots and studs, location grooves, knife edge front plate bores and much much more. Cross works with you to find solutions.

Our dedicated customer service teams are waiting to hear from you. To reach the right team please give us brief details and press submit.

You can also call our main office line on +44 (0)3301 224 400.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |